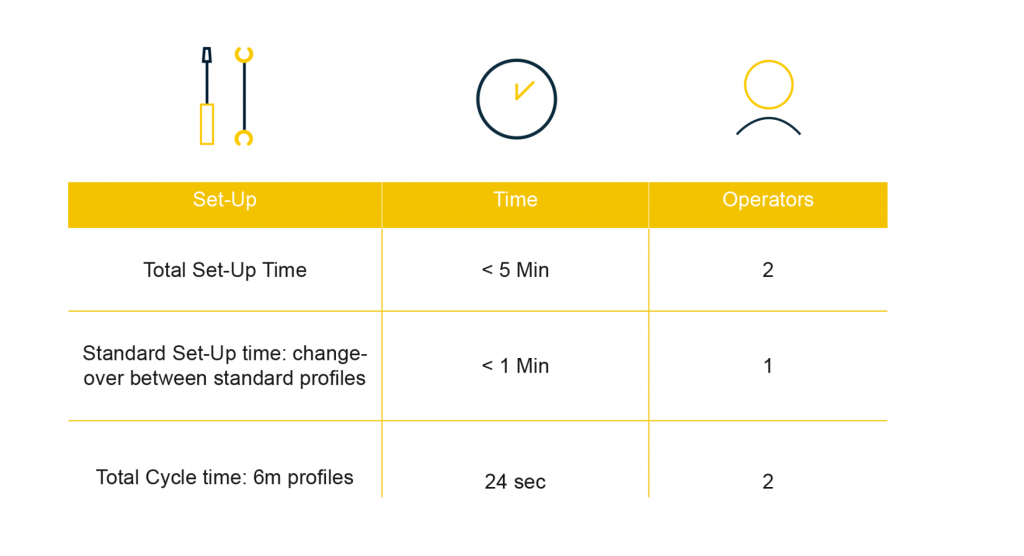

Power set-up

156 m² is all you need for a power set-up, with only 2 operators. The ‘buffer return’ evacuates the assembled profiles behind the second operator, who unload the profiles while the fisrt operator is preparing the next profile. This smart logistic set-up delivers ‘best-in-class’ results for efficient production.